Offshore

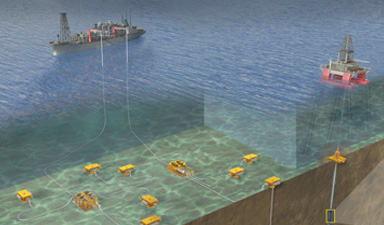

Dependable Deep-Sea Solutions

Our nickel and titanium alloys, CRA OCTG products, and umbilical tubing help you succeed in the most difficult conditions.

Engineering Offshore Advantages

Offshore conditions are like nothing else on earth. E&P operators must contend with the additional difficulties of high temperatures, high pressures and extreme corrosion.

PCC Energy Group is engineering the alloy and process solutions to overcome these unforgiving challenges.